Rail inspection | GEISMAR has the preventive answer

Since 2008, in order to meet a growing demand for preventive inspection of railway infrastructures, GEISMAR has launched and expanded a range of non-destructive rail inspection solutions and technologies. Ranging from hand-pushed trolley to onboard modules on autonomous railway vehicles, GEISMAR solutions adapt to different budgets and rail networks (metros, tramway depots, railroads, …), while maintaining the accuracy and reliability of measurements.

What are the inspection needs of rail network managers?

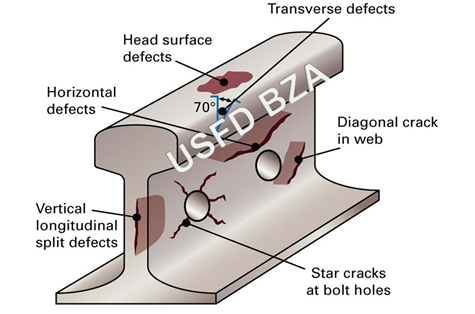

- Ensure track safety by preventive inspection of rail defects to reduce the risk of train derailments and interruptions to rail traffic;

- Improve inspection efficiency to reduce the time traffic is interrupted and the number of personnel on the tracks;

- Guarantee the traceability of measured data on the rail network;

- Have more ergonomic inspection solutions to ensure operator comfort and ease of use.

http://studiumbook.com/defects-in-rails/

In order to avoid dismantling the track for a posteriori inspection, non-destructive rail inspection methods are available on the market. Also called NDT (Non-destructive testing), they use electromagnetic or acoustic waves. GEISMAR has chosen solutions using ultrasonic and eddy current technologies.

Why these ultrasound and eddy current technologies and what are the differences?

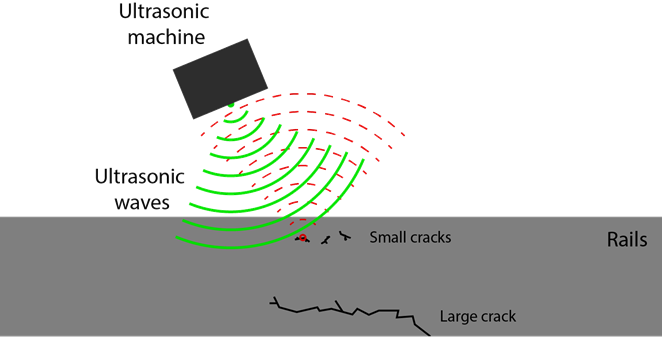

As in an ultrasound scan, acoustic waves, ultrasonic waves (high frequency waves between 1 MHz and 10 MHz), are used to probe the rail and obtain a three-dimensional representation of its internal structure. Indeed, when the emitted ultrasonic waves penetrate the rail, they may encounter irregularities, discontinuities such as cracks. These defects disturb the shape and speed of the wave which, when it exits the rail, induces a different signal compared to a wave that has not encountered a defect. From these signal differences, a computer is able to reconstruct the volume of the rail and to display precisely the position and shape of the defects. In practice, the higher the frequency, the more energy the ultrasonic wave has and the more sensitive it is to smaller and smaller defects.

https://ocw.tudelft.nl

The problem is that the ultrasonic technique only inspects the volume of the rail and therefore only highlights its internal defects (often related to metallurgical problems). It therefore does not make it possible to locate open cracks leading, for example, to the upper part of the rail head. Moreover, this technique requires a close mechanical coupling between the rail and the collector and cannot be considered in an operating context.

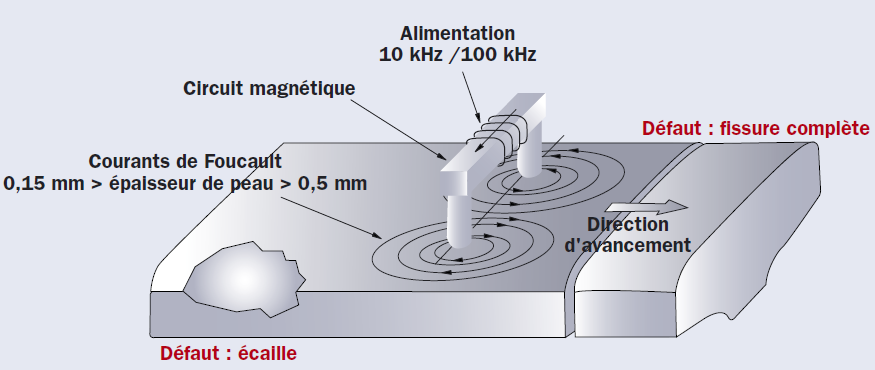

In order to better investigate these surface defects, currents are induced in the material to be analyzed (which must therefore be conductive like the rail) thanks to the excitation of a coil that creates an alternating magnetic field. This is called eddy currents.

MESURES 750 – DECEMBRE-2002

These inspection technologies are a must for infrastructure managers and contractors specializing in non-destructive testing. Preventively, the condition of the rail network is regularly inspected to ensure the safe passage of rail traffic and to anticipate maintenance plans such as track renewals.

What track inspection solutions does GEISMAR offer?

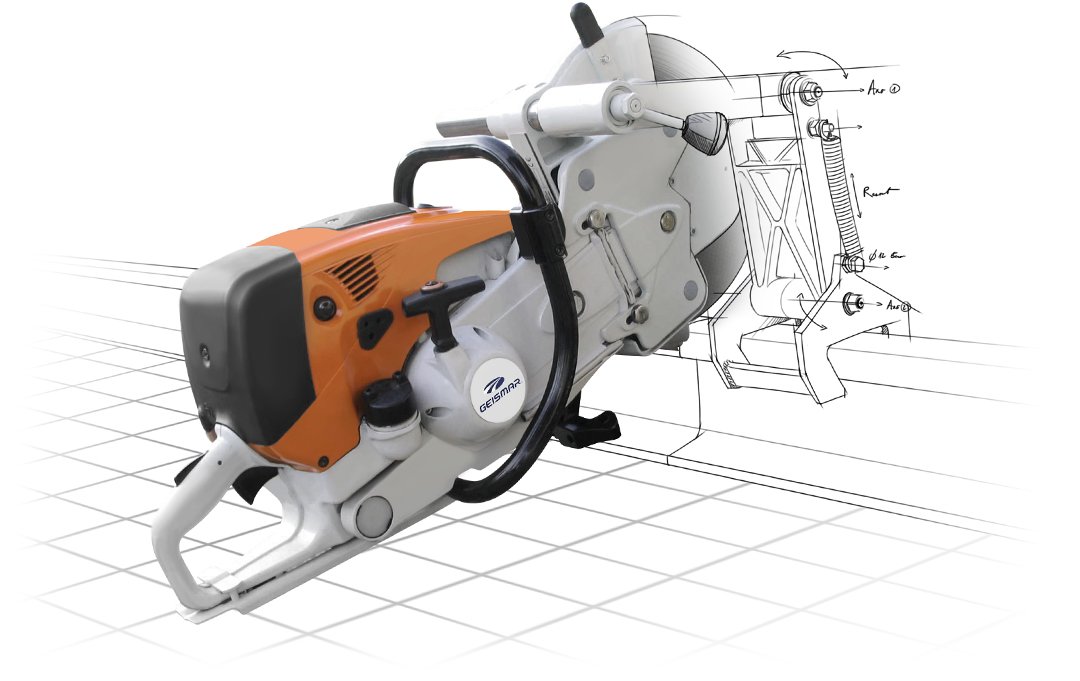

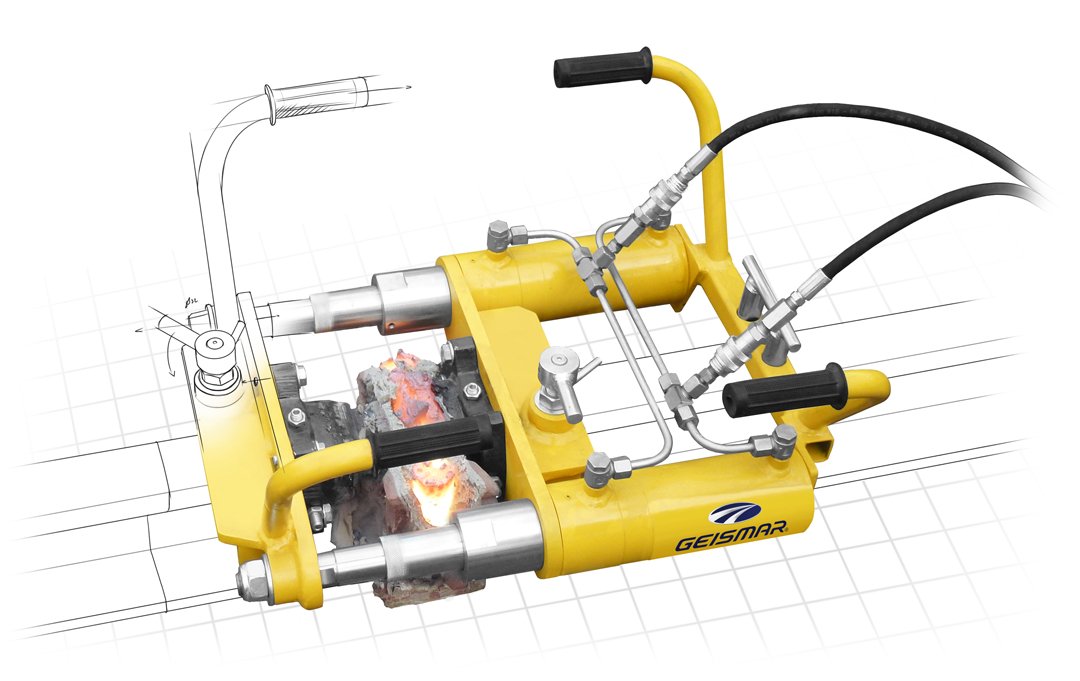

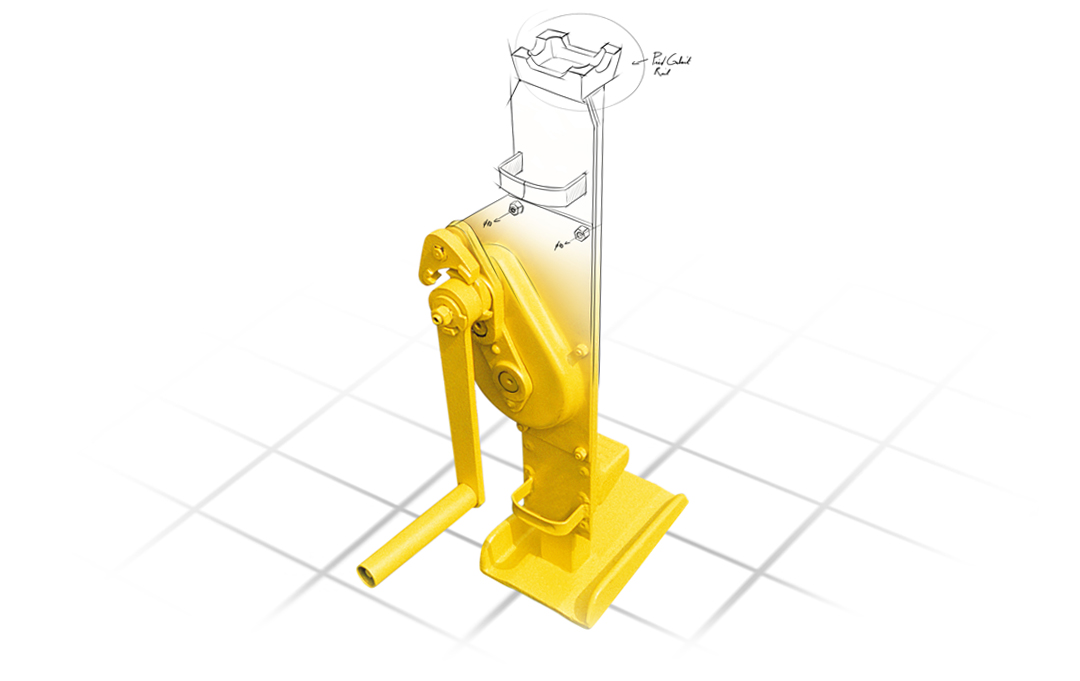

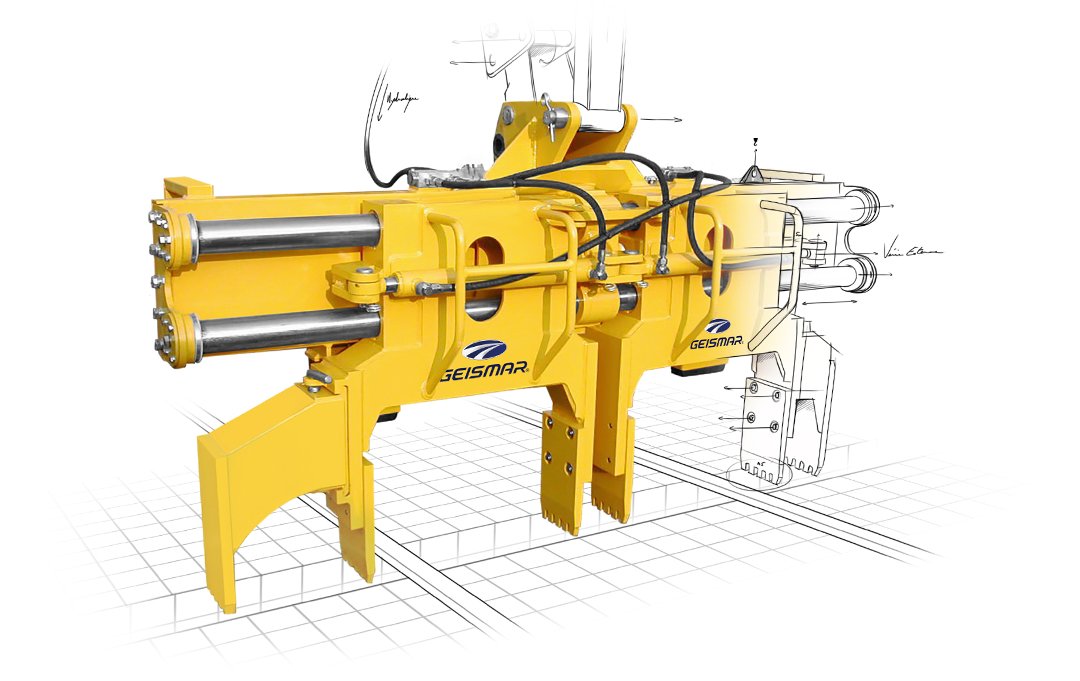

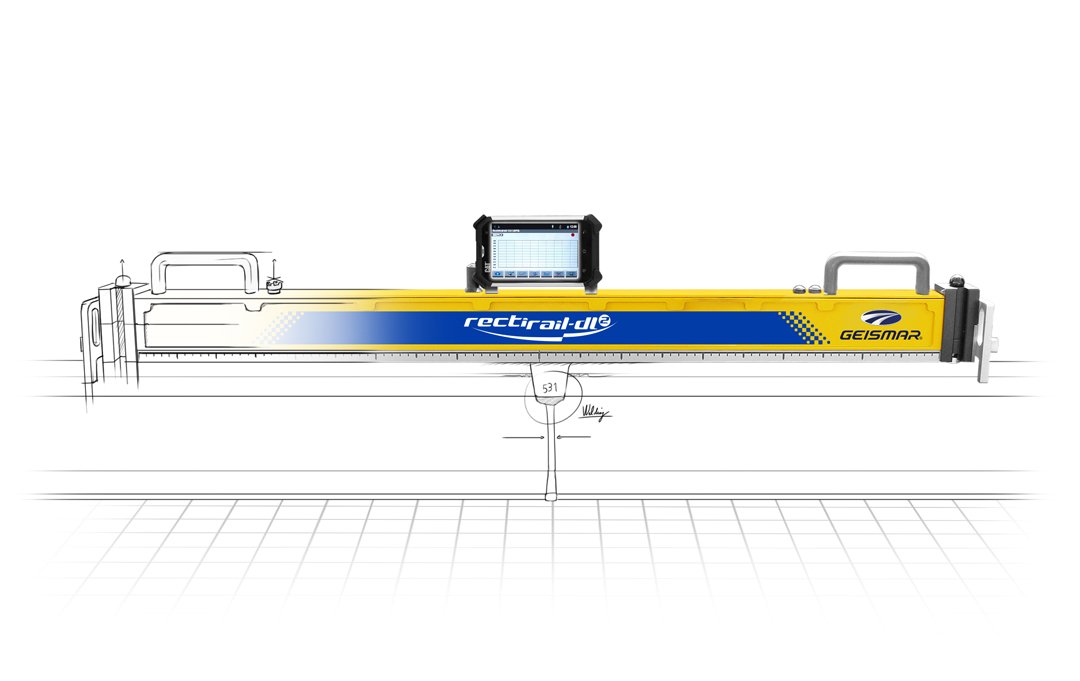

- Head scanners for ultrasonic verification of suspect defects in rail head

- Use: static intuitive 3D representation

- Stand-alone system, with its own electronics, or as a plug-in option for all 2 rail ultrasonic systems (EGO-US, FILUS X27, VIGILIS400, VMT/VMB)

- Type of rail: flat bottom or grooved

FLW-US

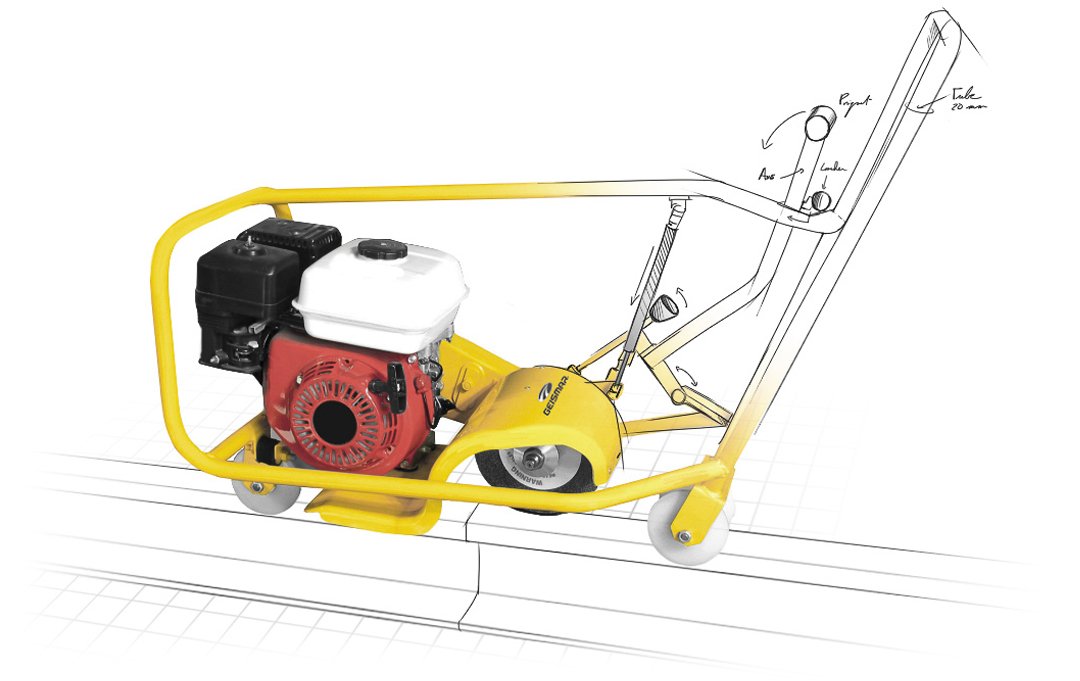

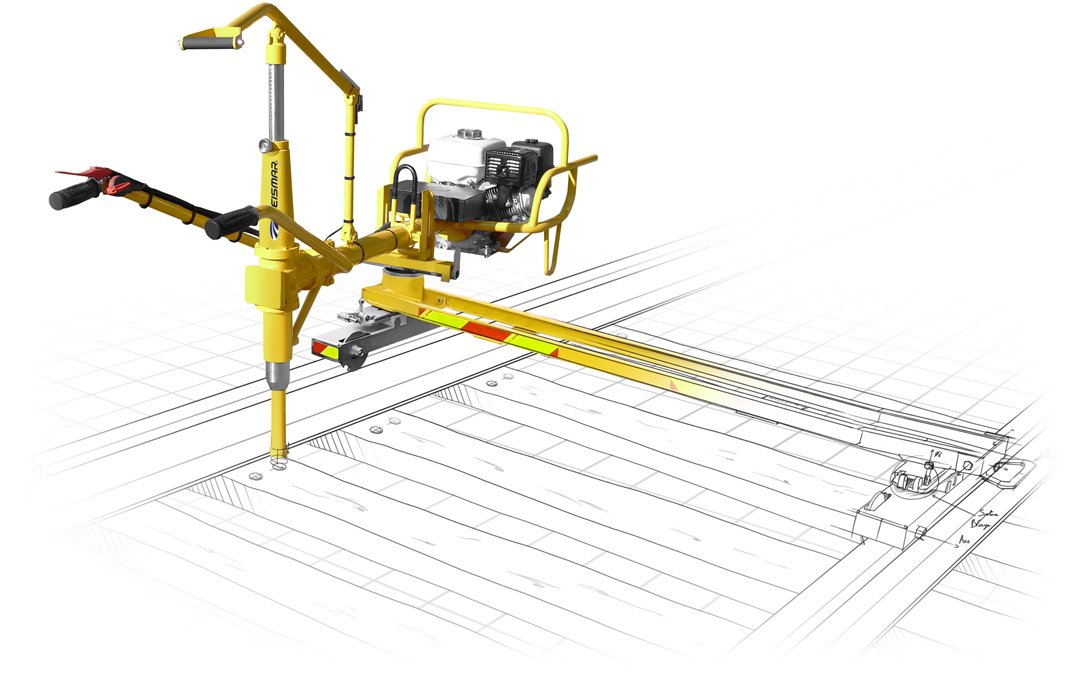

- The hand-pushed ultrasonic trolleys

- Use: local inspection of internal rail defects (less than 5 km per day)

- Rail inspection speed: 5 kph

- Type of rail: flat bottom (wheel or ski probes) or grooved (ski probes)

FILUS X17: mono rail | FILUS X27: dual rail

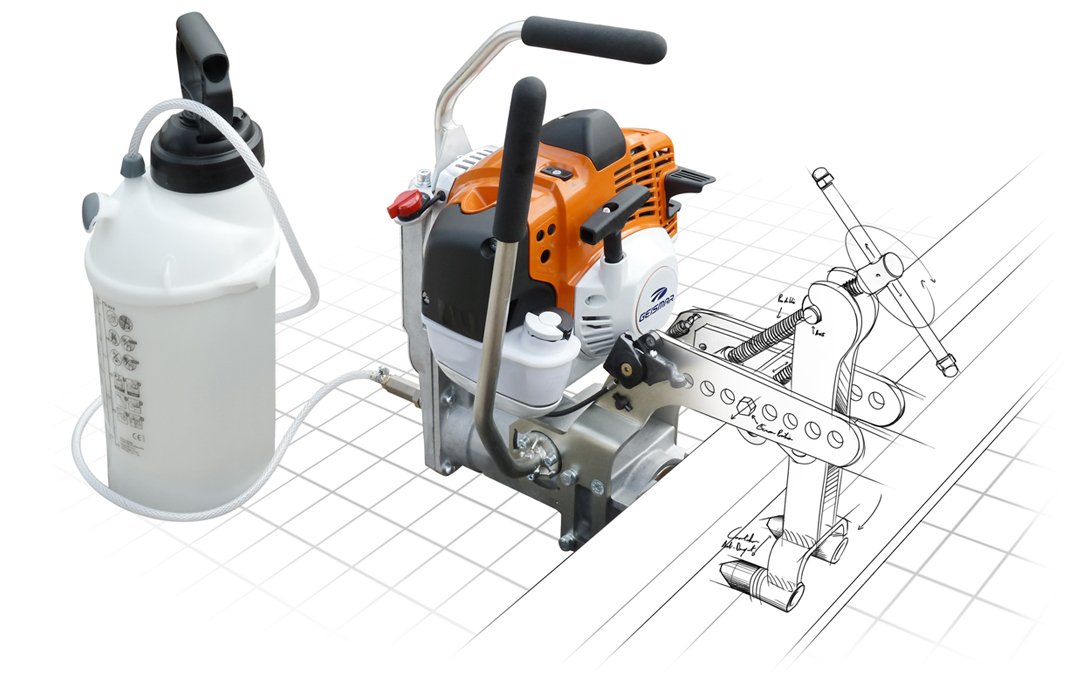

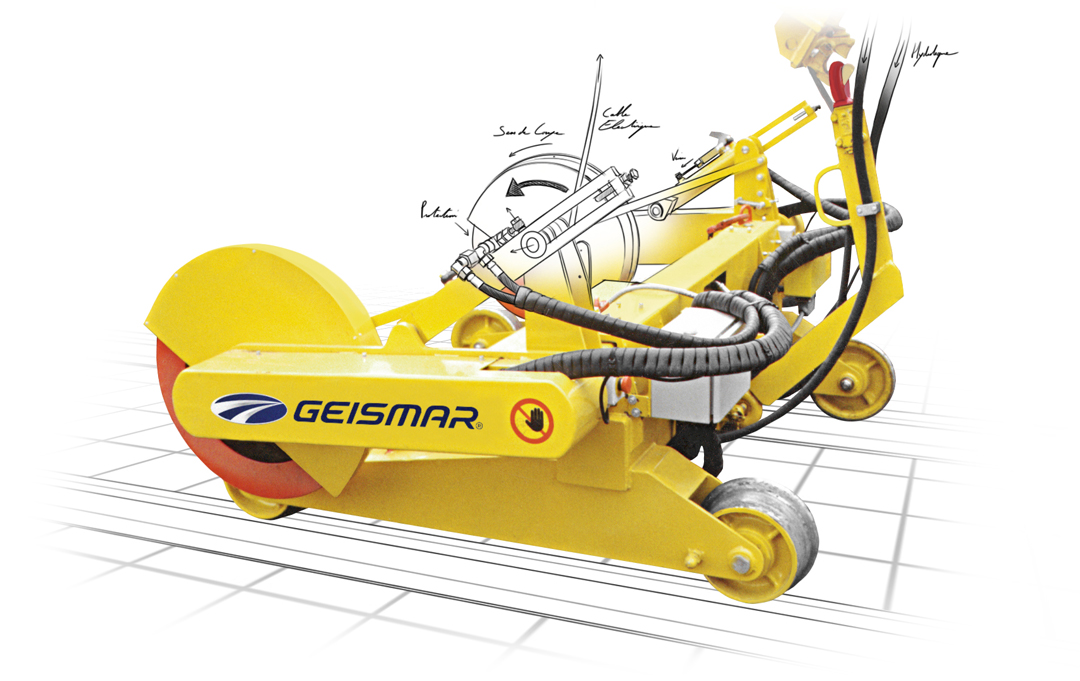

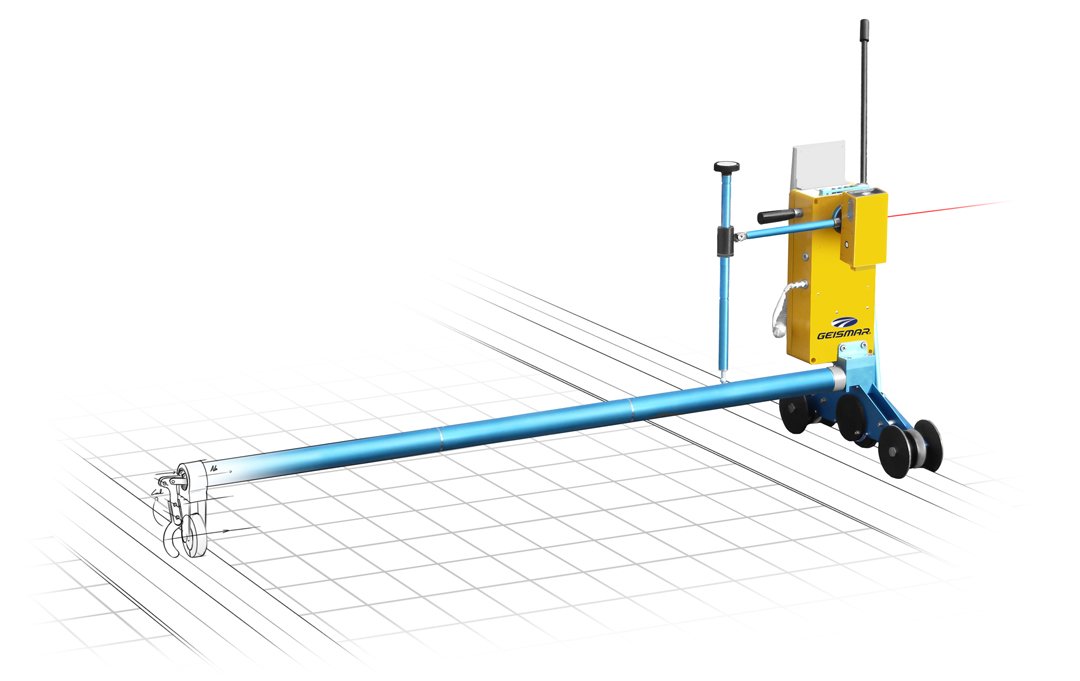

- Hand-pushed eddy current trolleys

- Use: local inspection of surface defects (less than 5 km per day)

- Rail inspection speed: 5 kph

- Type of rail : flat bottom

FILUS EC-1: mono rail

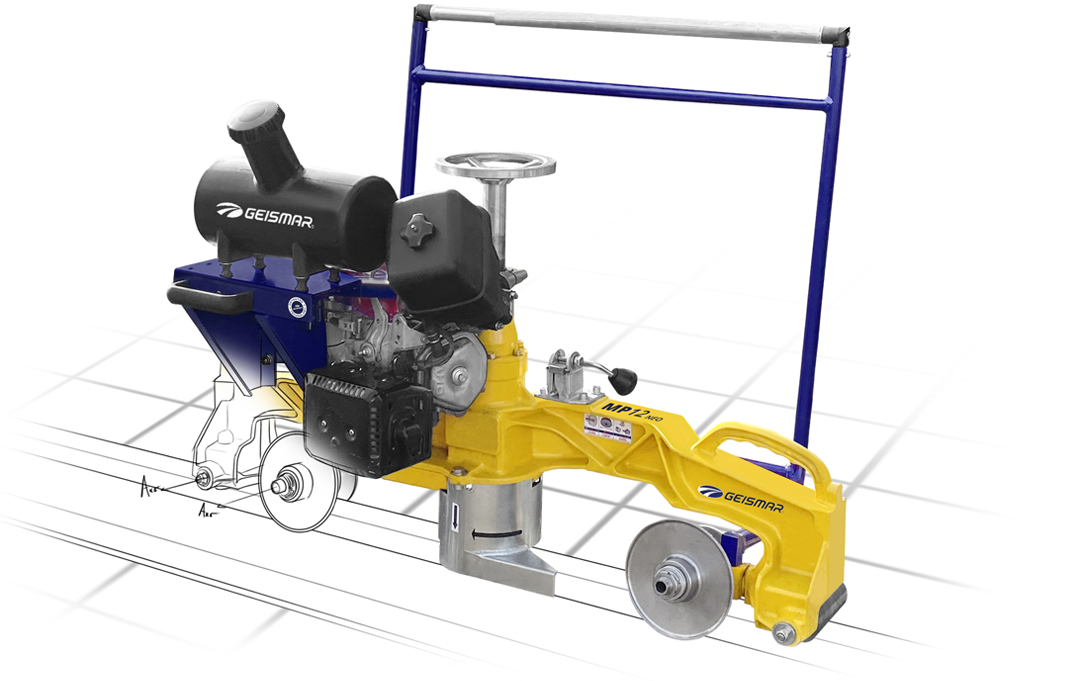

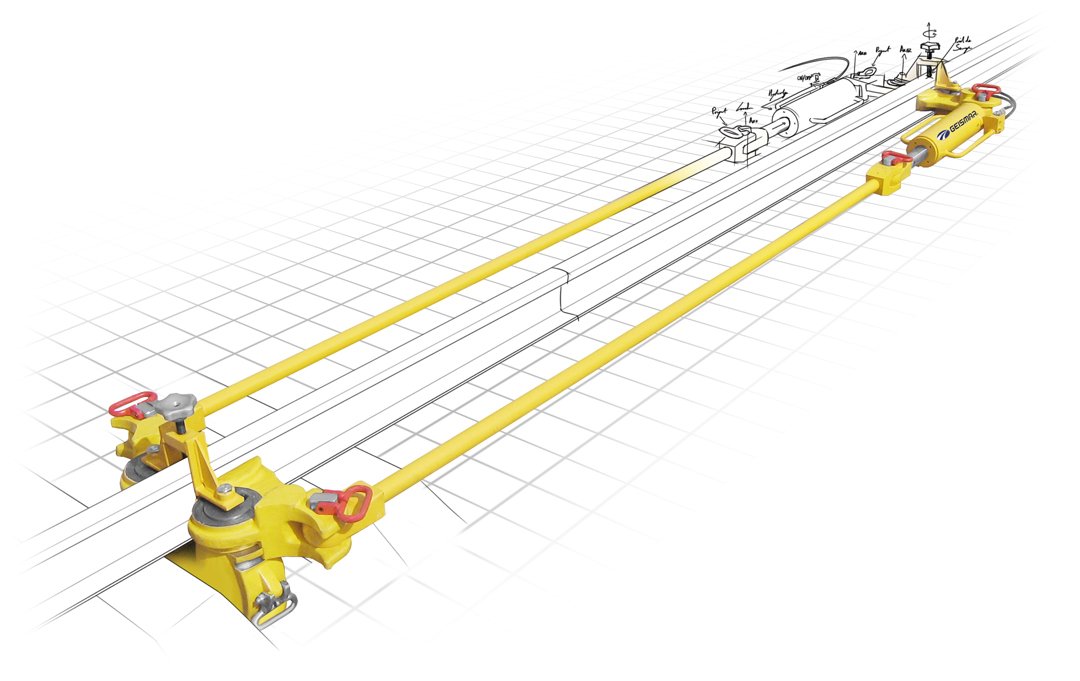

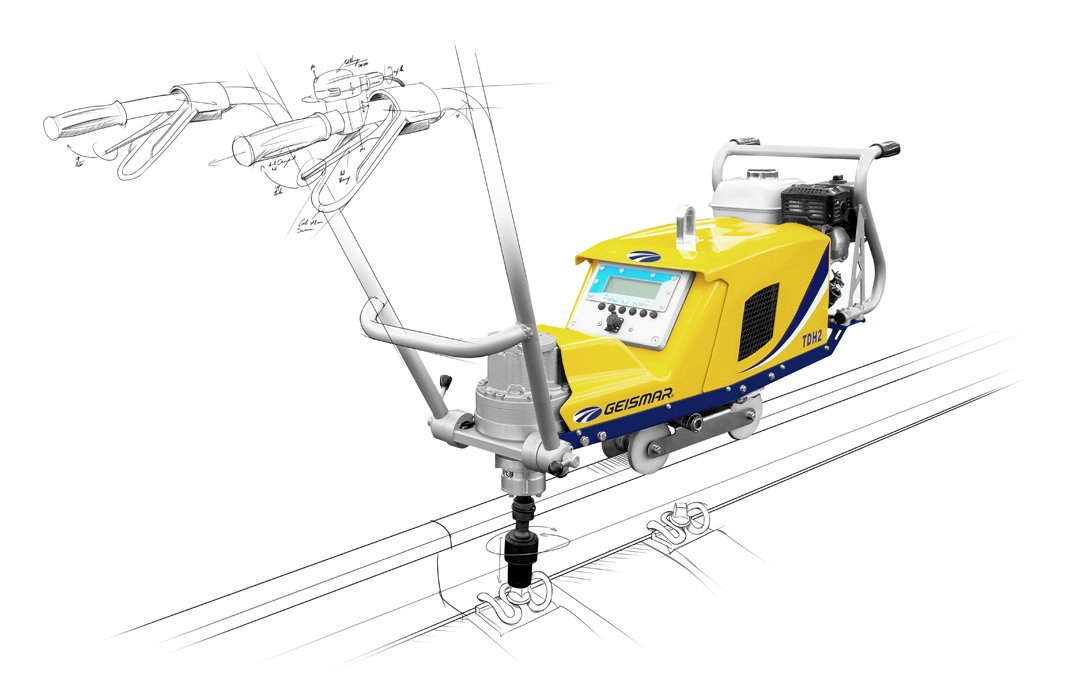

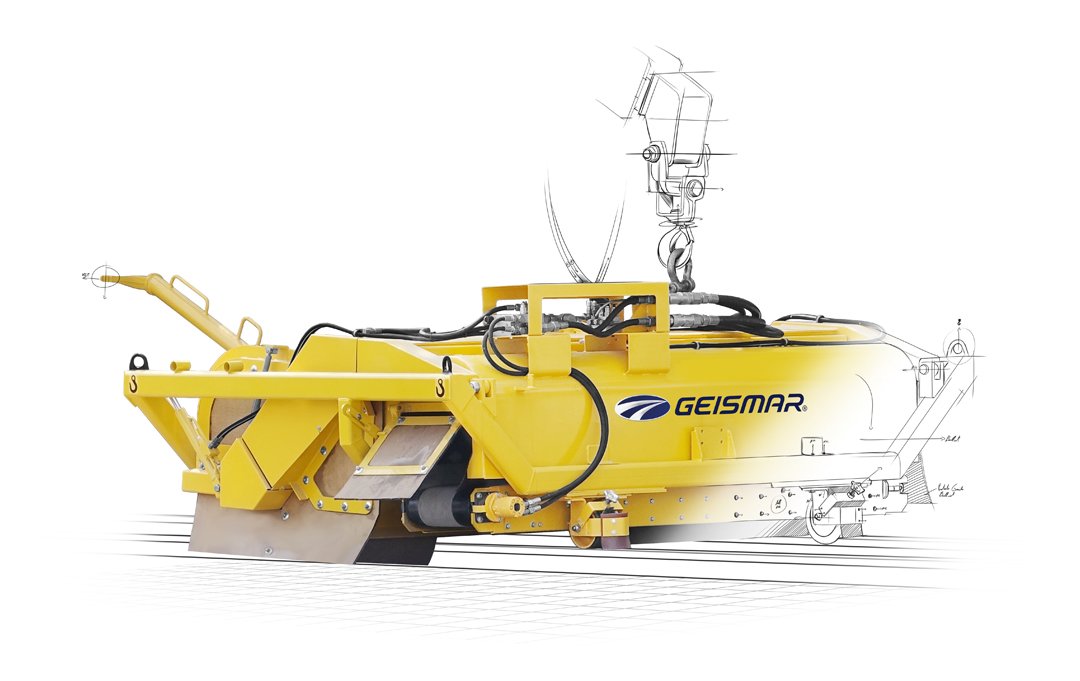

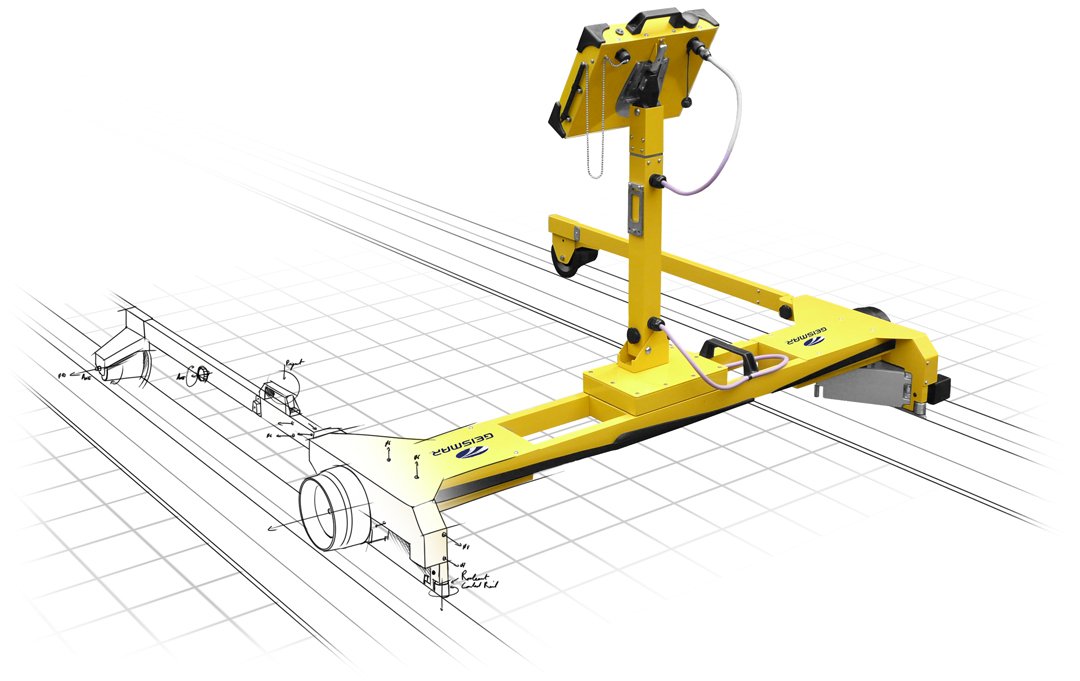

- Ultrasonic self-propelled battery-powered trolleys

- Use: inspection of internal rail defects (less than 50 km per day)

- Rail inspection speed: 10 kph

- Type of rail: flat bottom (wheel or ski probes) or grooved (sliding probes)

EGO-US: electric motorization on batteries

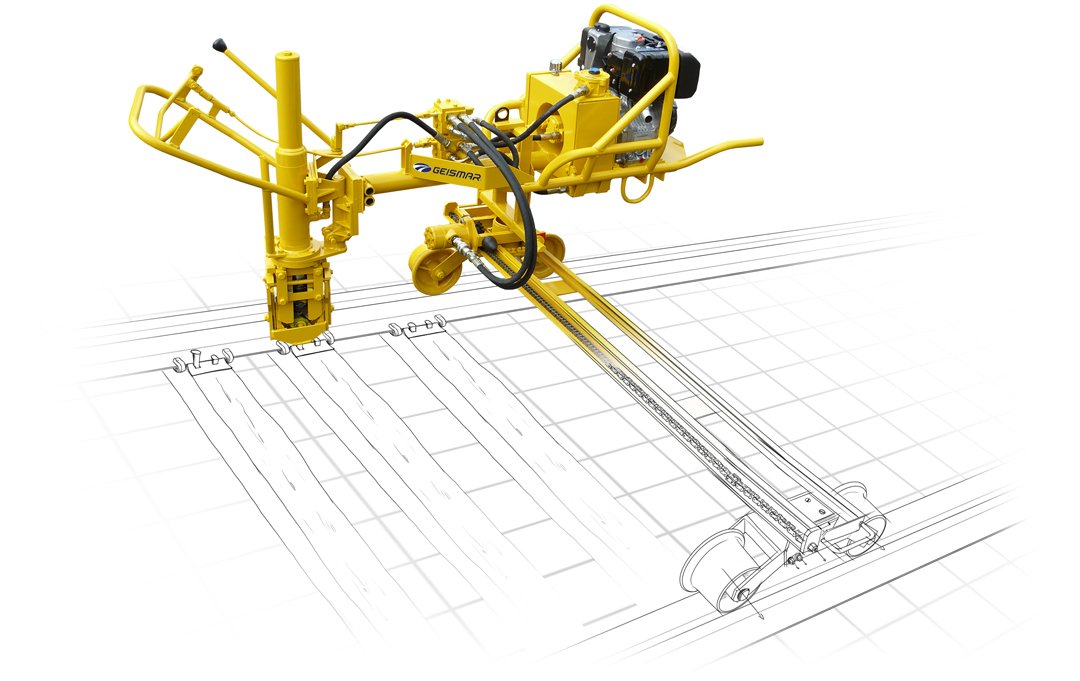

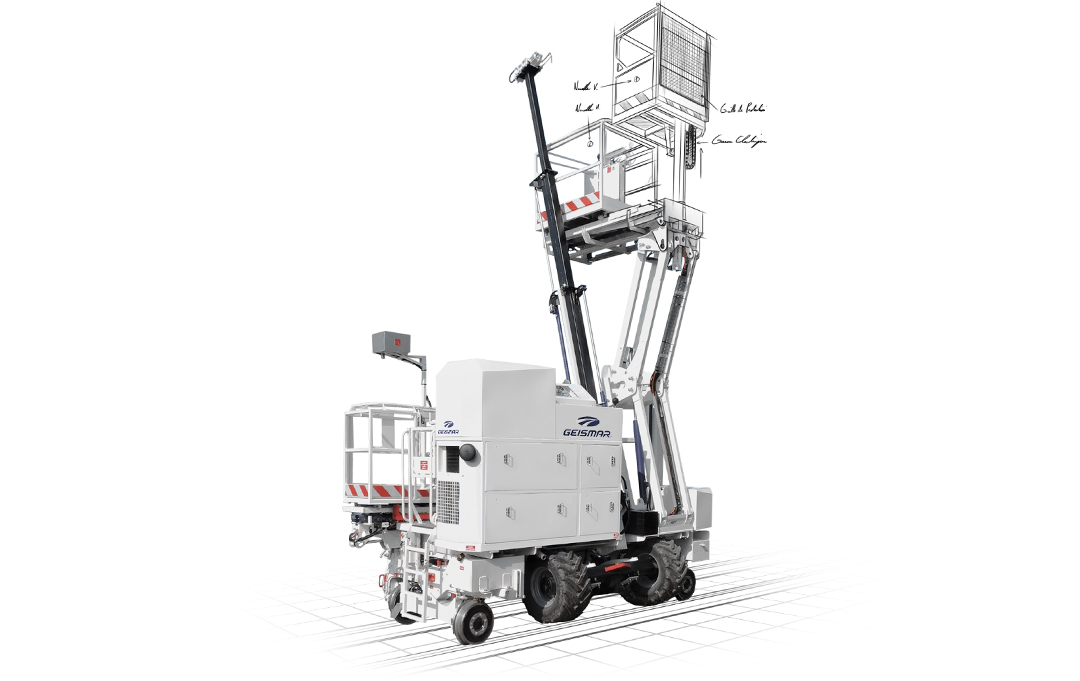

- Light rail vehicles

- Use: inspection of internal rail defects (over several tens of km per day)

- Speed of auscultation: 20 kph

- Type of rail: flat bottom (wheel probes)

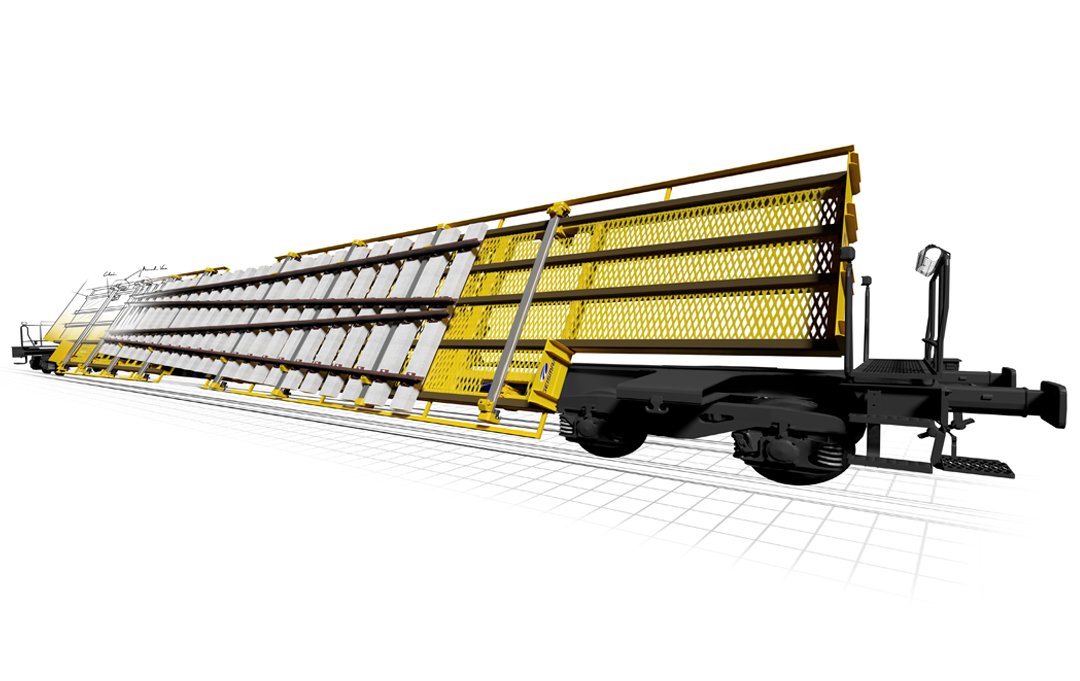

VIGILIS 400 MT US: measurement, track inspection and personnel transportation

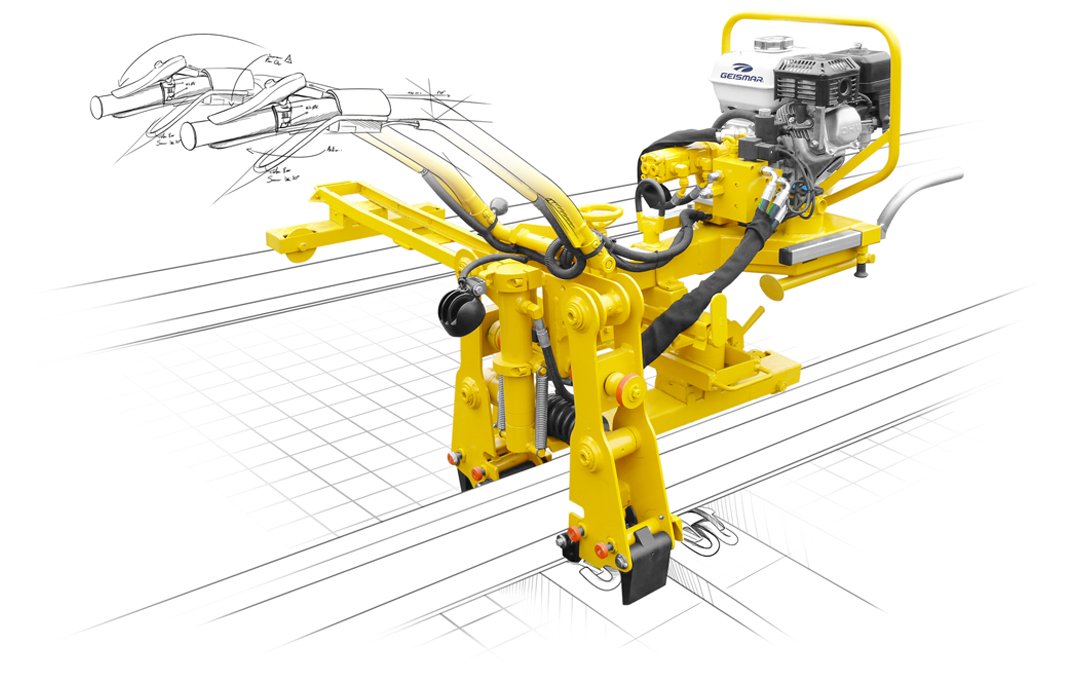

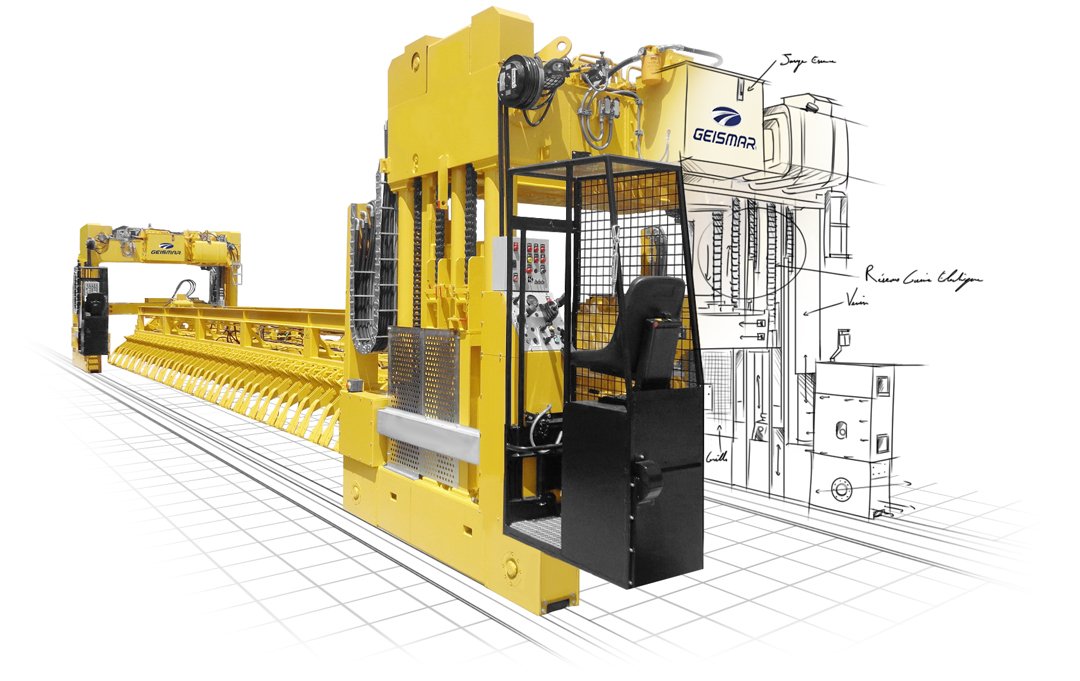

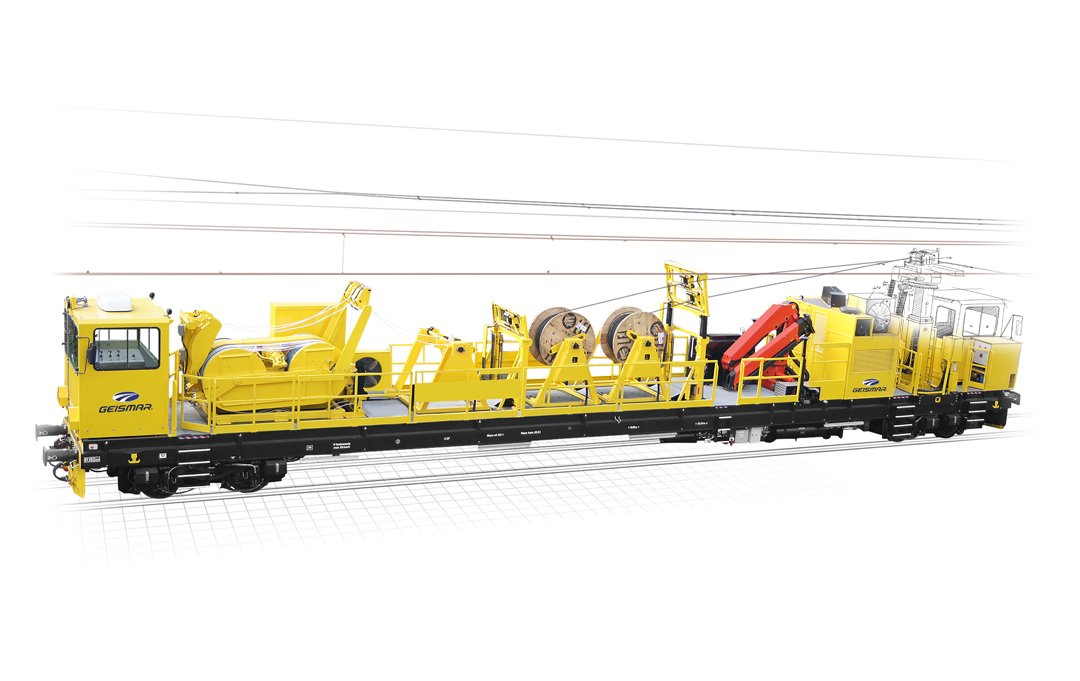

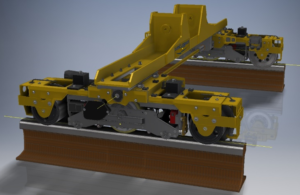

- Heavy rail vehicles with axles (VMT) or bogies (VMB)

- Use: inspection of internal rail defects (over several tens of km per day)

- Rail inspection speed: 50 kph

- Type of rail: flat bottom (wheel probes)

VMT 765 MT US C: rail axle track motor car for measurement, track inspection and catenary inspection

VMB 2014 MT US: rail bogie track motor car for track measurement and inspection

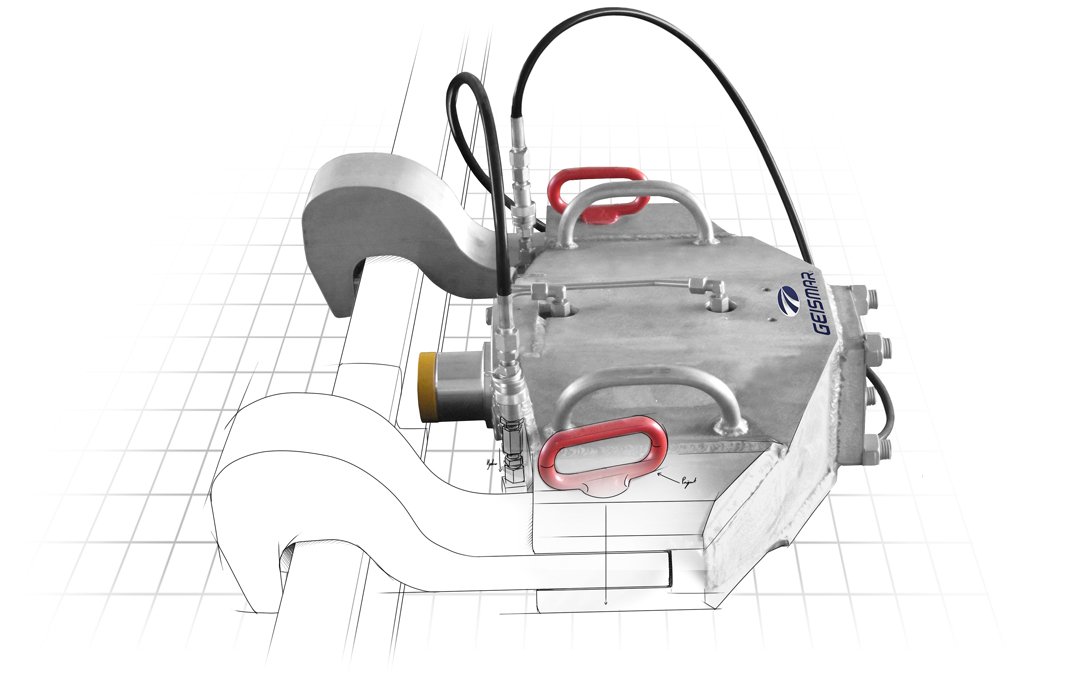

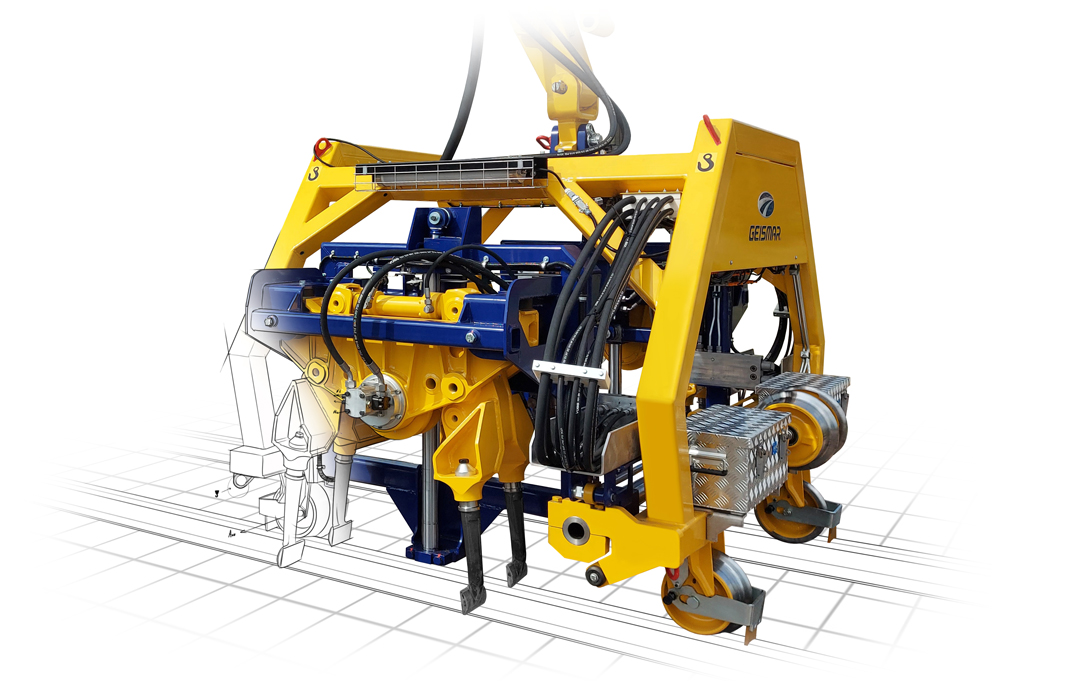

These light and heavy rail vehicles consist of a module capable of simultaneously and continuously inspecting both rails of the track for a number of defects :

- transversal flaws in the head of the rail (kidney-shaped defects)

- longitudinal flaws over the whole height of the rail

- star cracks around bolt holes;

- vertical cracks in welds;

- porosity and inclusions in thermite welds;

- corrosion defects at the rail foot;

The system can be installed under a wide variety of vehicles simply by changing the unit’s main beam. The system is fitted with a pair of single wheel probes, each containing 11 transducers and compliant with EN16729-1.

Chassis mounted under light rail vehicles (VIGILIS 400) and heavy rail vehicles (VMT/VMB)

What are the differences between ski and wheel probes?

Ski probes

Wheel probes

What new benefits does this range bring?

The sliding or rolling probes interface with a new multi-channel ultrasonic unit. The electronics and software are identical for all module choices. This saves time during commissioning and during routine use as well as providing better after-sales support. Sold in more than 20 countries, these different rail inspection technologies have versatile uses and can be adapted to different measurement campaign configurations and budgets.

For technical sales information, please do not hesitate to contact Karl Walters, product specialist for non-destructive testing technologies at GEMS – a division of GEISMAR UK (k.walters@geismar.com – +44 759 022 9653).

Log in

Log in