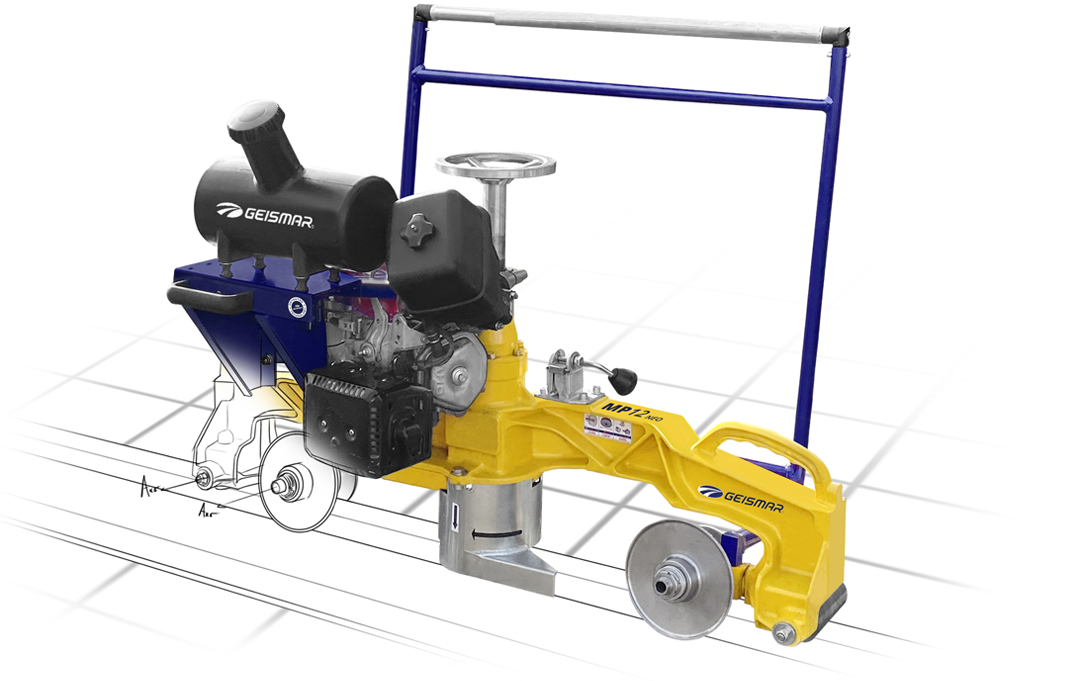

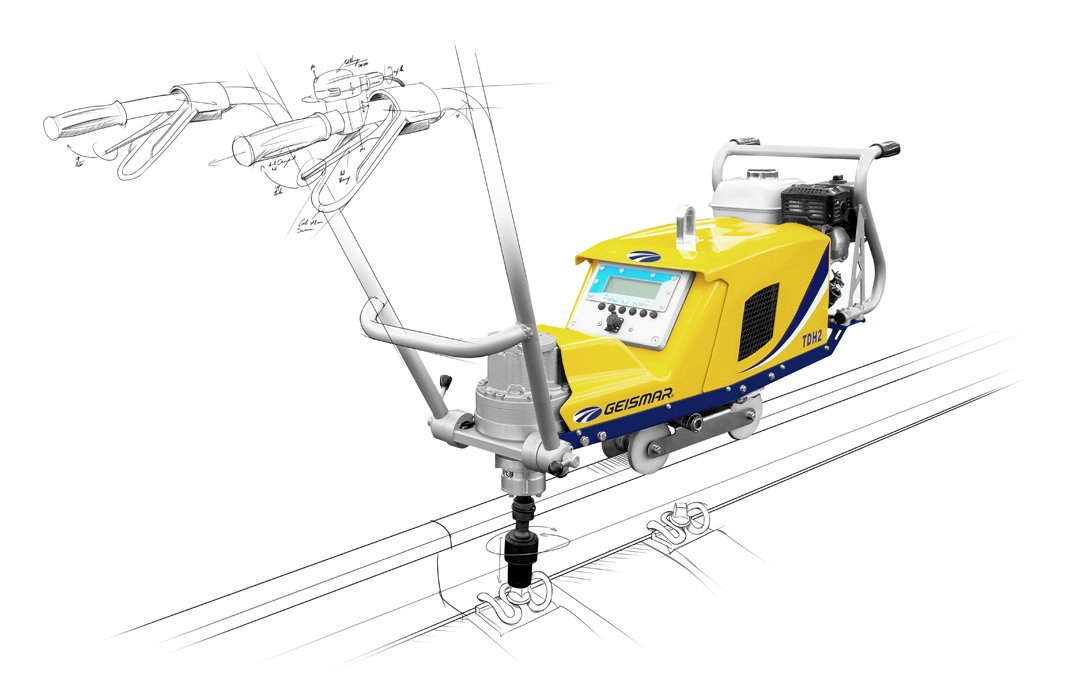

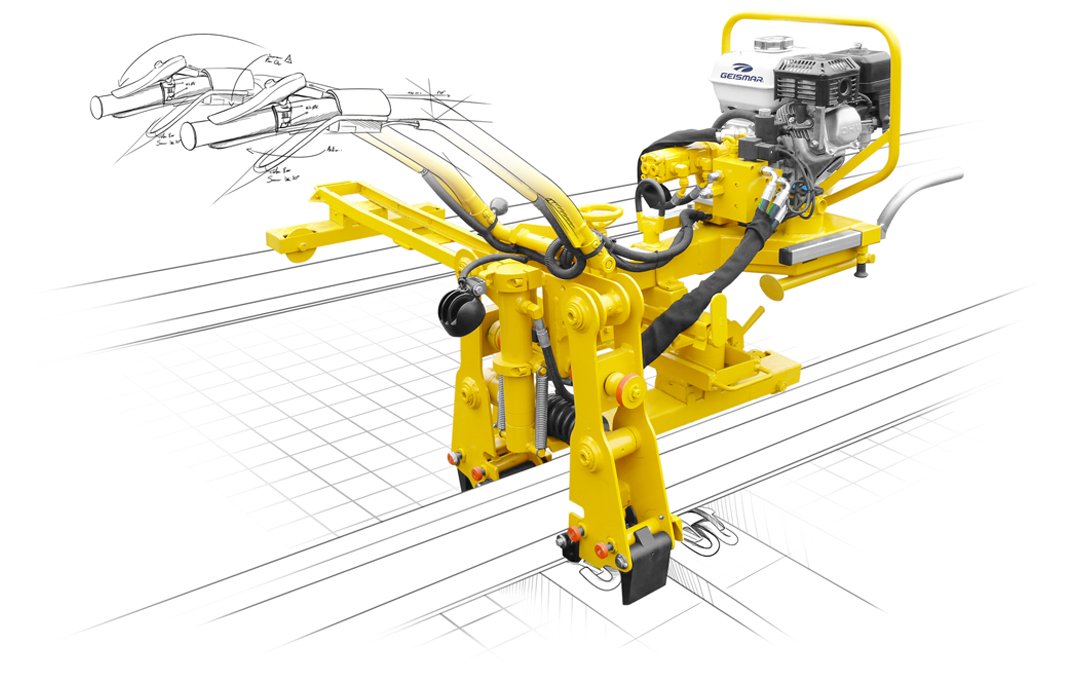

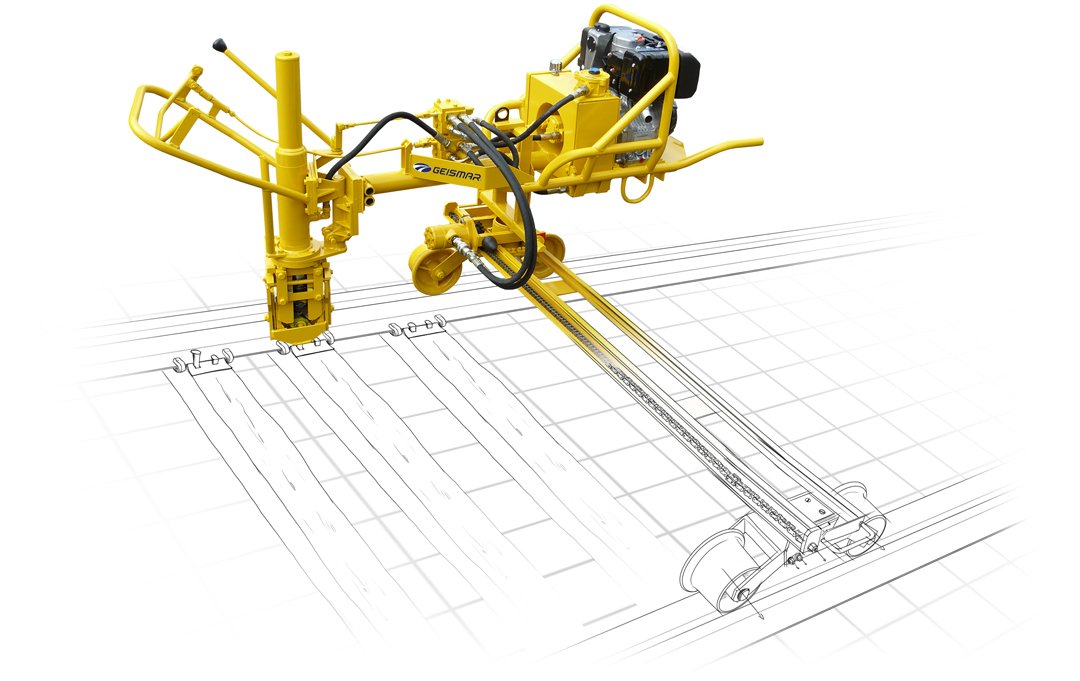

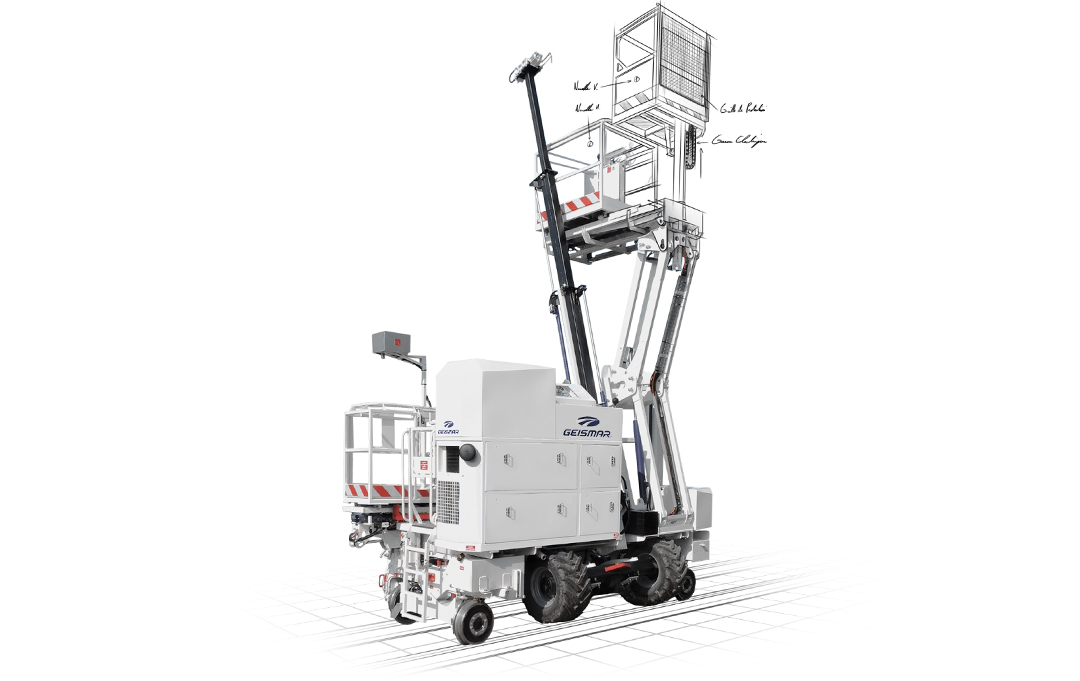

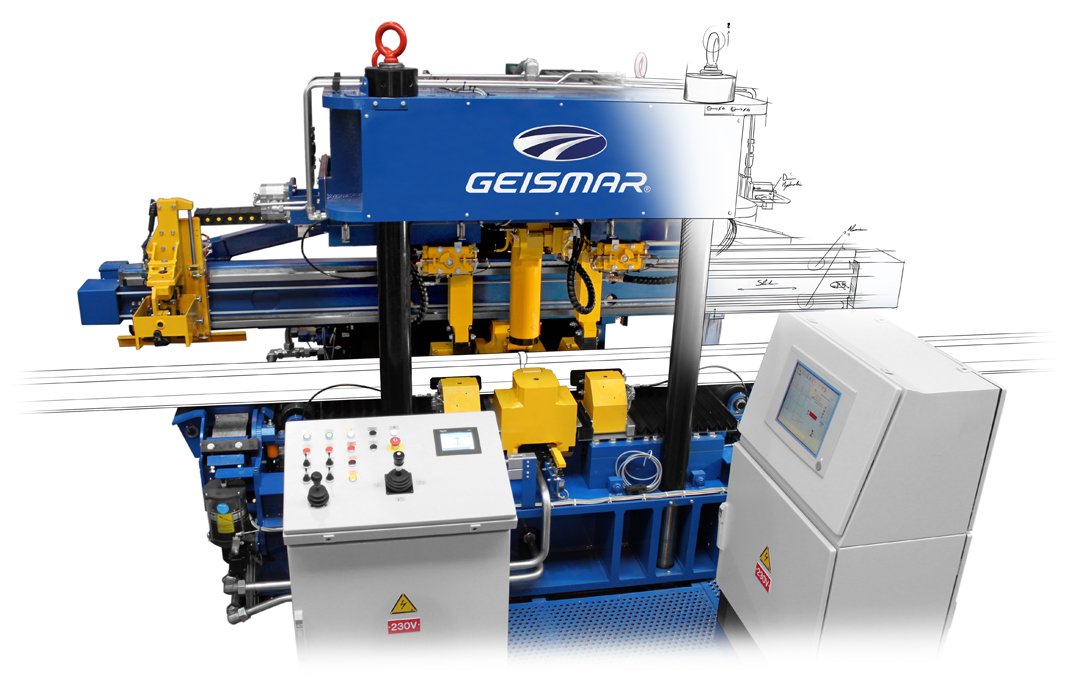

Anticipating the global movement towards solutions that preserve the environment, improve the comfort of workers and minimize negative impact on the neighborhood, Geismar proposes a new global approach towards a sustainable railway world “the sustainable way to rail” which consolidates all its innovative electrically-powered solutions under the name Activion systems.

Select your region

×

UNAUTHORISED ORDER

Only customer business addresses are allowed to order from the Geismar Store.To order by phone, please call +1 847-697-7510

Log in

Log in